Maximise the material recovery of your devices that are beyond economic repair

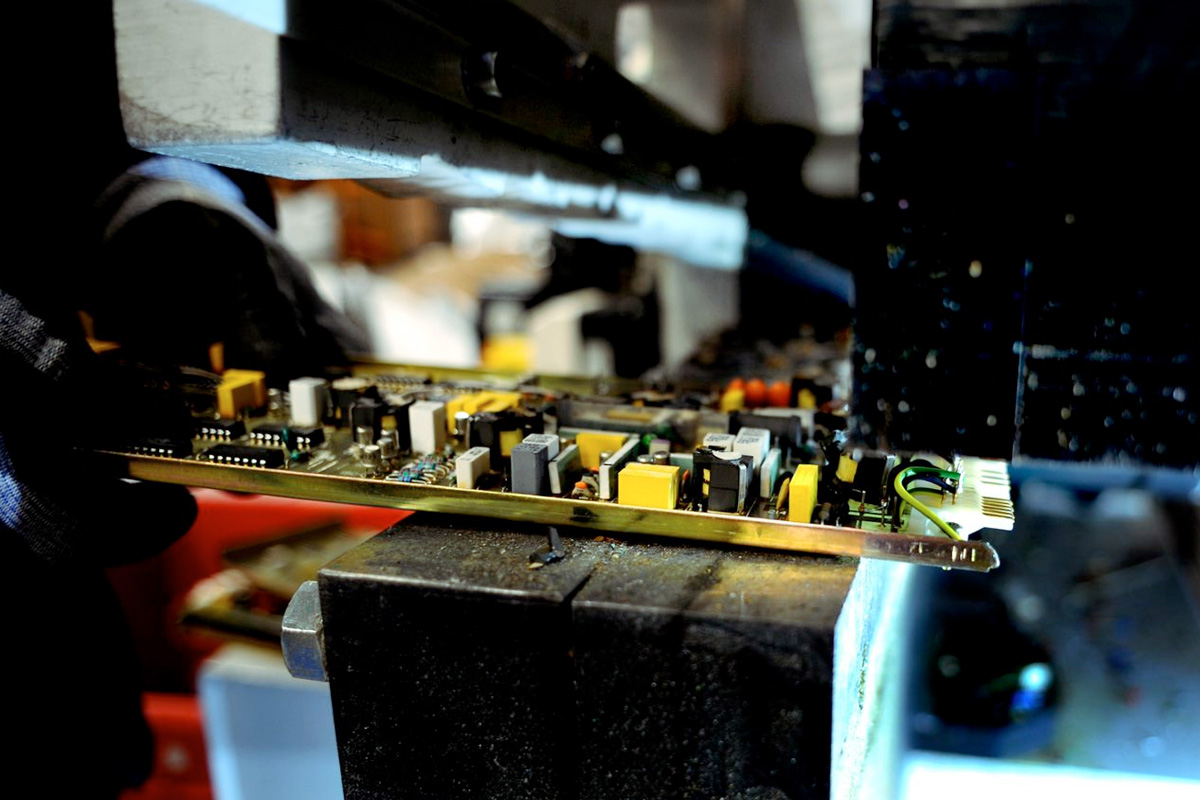

For devices that cannot be reused or are beyond economic repair, we employ sustainable recycling processes. From our state-of-the-art recycling facilities, which house advanced equipment including PCB and cable granulators, we can process large quantities of IT equipment.

All materials used in the production of devices are recovered and reintegrated into manufacturing streams. They find new purpose as items like traffic cones or rubber matting. We consider end-of-life technology as a valuable resource, not e-waste.

Scope 3 emissions represent the emissions that an organisation is indirectly responsible for up and down its value chain. For example, in an organisation that manufactures products, there will often be significant carbon emissions from the extraction, manufacture and processing of the raw materials.

All businesses must work towards net zero carbon emissions. By working with n2s and reusing, reselling or recycling your legacy IT equipment your business can ensure that components can be reused, and no equipment ends up in landfill. In turn, this will reduce your Scope 3 carbon emissions.

When we process legacy IT, we look to do so in the most sustainable way possible through:

Upgrading and deploying devises back into a business.

Refurbishing and returning equipment back to the market for others to use.

Recovering the raw materials that can be redeployed to the manufacturing stream.

In the UK alone 1.5 million tonnes of e-waste is generated annually

Over 200,000 tonnes of UK business electricals are improperly disposed of each year.

By working with n2s, your business can ensure no IT equipment ends up in landfill and its components can be reused.

n2s have a zero-to-landfill policy and endeavour to minimise and advise on reducing waste. Reaching carbon net zero requires us to rethink how we do things and shift from a linear to a circular economy.

The precious metals required to manufacture new technology are often mined from conflict zones. The process uses huge amounts of water and energy, damages biodiversity and creates a toxic environment.

In addition to this, current methods of refining e-waste use harmful chemicals and produce toxic emissions which are damaging to all life.

Through sustainable innovation, we are developing methods to safely refine precious and critical materials.

n2s devised a work program that facilitated the prompt exit from the data centre, savings approximately £1-1.2 million in lease charges.

90% of the servers were remarketed, generating sales values surpassing 130% of the originally predicted value.

Sign up with your email address to receive news and updates.

©2024 Network 2 Supplies Limited. All rights reserved.

Eldo House, Kempson Way, Bury St. Edmunds, Suffolk, IP32 7AR • Company number: 04617783 • VAT number: 807724131

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo. Consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus.